The First Step in the Product Design Process

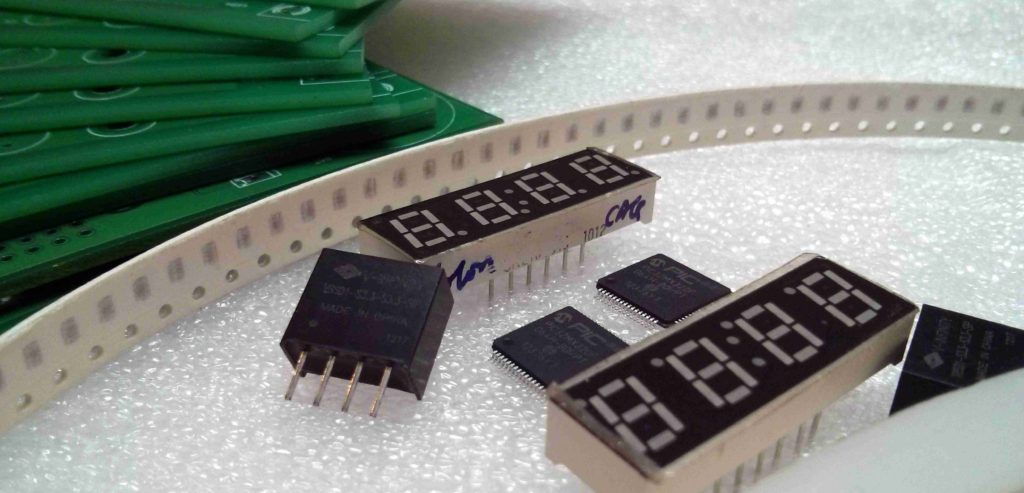

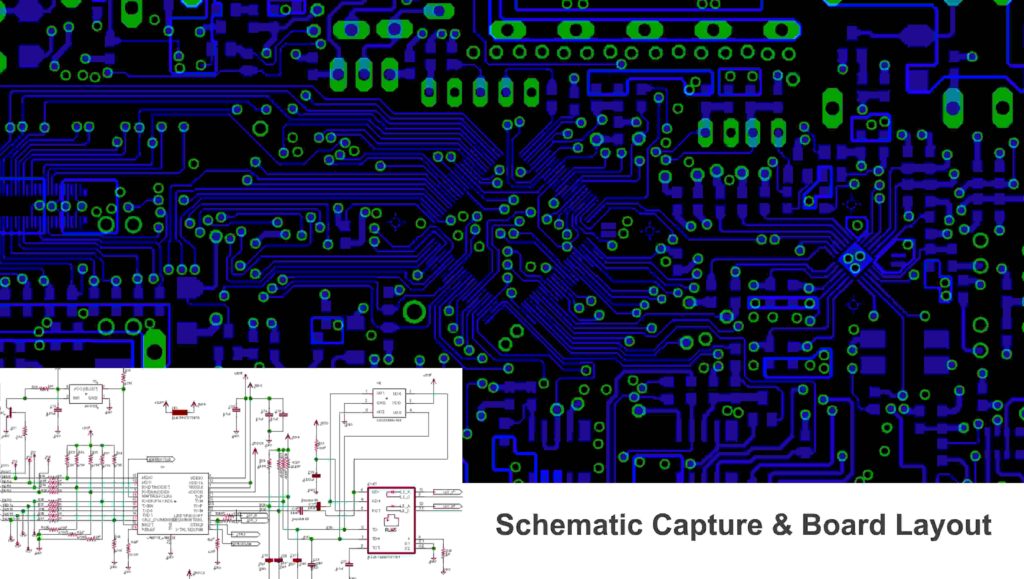

Components – PCBs – AssembliesPCB and PCB Assemblies are first step in the Product Design Process. PCBs could be add-on PCBs on development platforms OR the actual PCBs that will be used in creating the product. We create the hardware design and capture the Schematics of the design. This is the outcome of experiments, know how of circuit design principles, simulations and rapid prototyping. This then results in PCB component selection, placement , form factor decisions, Bill of Material, Engineering of the overall assembly, PCB layout and Gerber File Generation. The Gerber files are sent to PCB manufacturers and components are procured. PCB assembly is typically done in house and the Board Bring Up happens thereafter to get the boards ready for firmware development.

Components – PCBs – Assemblies

Our goal is to get the design “first time right”, however certain constraints, design changes, component related issues result in spinning the board around. However maximum milage from the first turn-around is what we believe in and pursue. We have the right vendors in place from whom we can source reliable components, get prototype PCB / cable assemblies and cutomization done if needed. Our hardware team gets the board ready by writing driver and test code to ensure that the firmware developers get error-free hardware that they can use for coding and testing. Designs are done with compliance in mind and pre-compliance and compliance support is provided to ensure that products can be sold in the adequate geographies.