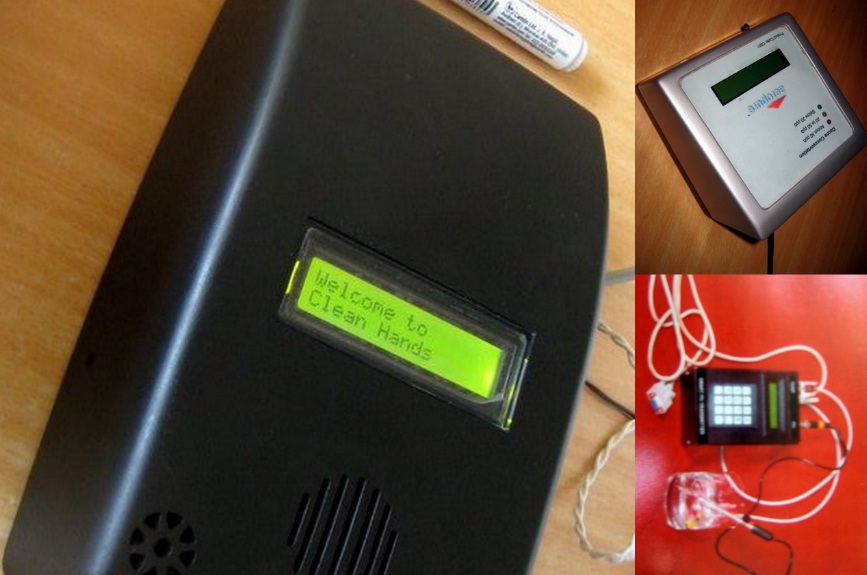

Enclosures First Electronics Later

Generic platforms and devices need to have an low-cost enclosure that can house the electronics. These are off the shelf enclosures that are selected before the design process begins. The mounting locations available in these enclosures decide the mounting holes in the PCBs. Cutouts are made on these enclosures to ensure that the cable harnesses / displays / connectes etc. can be accomodated. Labels are created that can fixed on the face of the enclosure that brands the product and provides information with regards to the device. These enclosures are typically wall mounted / DIN Rail mounted / table top / handheld. Low cost – fast – easy to implement are the pros … Lack of Industrial Design being the cons.

Electronics First Enclosures Later

Custom enclosures improve the brand of the product and give a custom look and feel to the overall product. Enclosures are typically created and rapid prototyped. Electronics is designed around these enclosures to make sure that the electronics fits properly, doesn’t foul and has all the usability aspects that were intended in the design process. Once the enclosures are finalized the molds are created for mass-manufacturing. This results in an overall increased time and cost upfront. Moreover the manufacturing costs go down significantly, design and product control is achieved and the branding aspect is taken care of.